Advantages and Disadvantages of Pneumatics

| ✅ Paper Type: Free Essay | ✅ Subject: Mechanics |

| ✅ Wordcount: 2102 words | ✅ Published: 23 Sep 2019 |

Table Figures

Introduction

The use of mechanisms that utilize compressed air or gases such as nitrogen when piped to be able to allow the transmission of force and energy is called Pneumatics (Woodford, 2018). The science as well as the technology of pneumatics has been in use for thousands of years; for example, the use of a blow gun by ancient hunters, who used the 6000in3 per minute capacity held by their lungs allowing the production of up to 3psi of pressure to send darts flying with their prey as target. After that the first compressors were made around 3000 B.C; these delivered tiny blasts of air that helped a fire get started (Brief History of Pneumatics, 2012). Then the 17th century the first vacuum pump that used air pressure was created by Otto Guerickle who was a German physicist but only after in the 19th century is when the world started opening their eyes to the possibility of effectively utilizing compressed air in a greater scale. During this century a couple of important developments were:

- An air compressor; which allowed for air to be compressed in series of cylinders was patented in 1829, this is what’s called a compound air compressor.

- In 1872 this type of compressor technology was enhanced further when cylinders began to be cooled by water improving their efficiency.

- The first big practical development was in 1867 when Alfred Beach, constructed a pneumatic subway train in New York. Displaying the ability of passengers being able to be transported end to end through a pipe by utilizing pneumatic power; the subway ran stretched the length of a block and in America it became the first of its kind, however permission was not granted for an extension and it was shut down.

- John Wanamaker who was American merchant, was the first to present pneumatic tubes in the United States Post Office, in the late 1800’s, allowing letters to be transported from one part of the building to another in a speedy fashion. The same system was installed in his store, the Wanamaker’s. there it was used to allow the transportation of cash to and from cashiers as well as other important documents from one part of the store to a another.

- 1871 saw the invention of the pneumatic drill by Samuel Ingersoll and later on came the pneumatic-powered hammer by Charles Brady in 1890.

The 1900s is where there was great advancement in pneumatics, as this is when pneumatic components began finding use in jet engines as axial-flow and centrifugal compressors. Progress in pneumatics continued with improvements in devices that saved in labour, this came as: machinery that assisted or was able to reduce the necessity for manpower, along with automatic control systems, tools and machinery. The late 1960s saw the initial digitally controlled pneumatic components beginning to be introduced into the market which again further help developing the manner in which these effective pieces of equipment came to play a useful part in our day to day lives.

The industry of pneumatics till this day continues to develop with the production of components by leading names offering that little bit extra which results in improvements in:

- efficiency

- performance

- as well as functionality

The ever-important role played by pneumatics can be observed today, in:

- its vital role in stabilizing gauges on an airplane in the unfortunate occurrence that there is an electrical failure. The Pneumatics allow the pilot the capability of still being able to maintain a clear understanding of, as well as, control over the important numbers that will aid him in making a safe landing.

- The ability possessed by modern pneumatic cylinders of providing fast and accurate power for applications of the low pressure sort, gives a range of industries, from: packaging to amusement park rides, medical devices to automation control; the ability to have simple and powerful yet safe controls. (Kyle, 2014)

For my report I will explain a bit about pneumatics; how they work, how they’re used, where they’re used, their disadvantages and advantages. The aim of this is to educated the reader and be able to provide a more understanding and insight on the science as well as different technologies of Pneumatic systems.

What is Pneumatics?

Explanation on Pneumatics

The basics pneumatics can be seen at work when you blow up a balloon, hold the air in it and then allow it fly wildly around the room, what you are doing the is putting air which is pressurized to use in a practical way. Pneumatic work in a similar manner to hydraulics which instead use liquid to allow force and energy to be transmitted. (Woodford, 2018)

Using the balloon is blown up and the released as an example you ae able to explain pneumatics further but still in a simple way. Air was blown out the lungs and inside the balloon; with every breath that is forced into the inside of the balloon a it is inflated, pushing out with force and acting against the air pressure as well as the elasticity of the rubber which is in turn pushing inwards from outside. So, meaning that a force (the breath pushed into the balloon) over a distance (which translates to the amount the balloon has managed to be inflated by) has been used: this in physics terms is called doing “work” on the balloon. Air has been compressed, then forced into the balloon and all this is under pressure. The compression a gas (such as air) stores energy in the gas, as it takes energy perform the work that compresses a gas and as we know energy cannot be destroyed only converted. This means the energy utilized to in the action of compressing the air into the balloon has not gone to waste, but in fact just been stored in the compressed gas as what is called, potential energy, which can used later. This action of inflating the balloon can be compared to filling up a small energy tank (or reservoir) which is constructed of rubber. When the balloon is let go of all that trapped gas is then released: causing it to expand and so its stored potential energy promptly reverts into kinetic energy, causing the balloon to be powered around the room by a jet of air. This could be looked at as a very basic kind, jet engine of sorts. (Woodford, 2018)

Pneumatics can have a wide-ranging definition, signifying that pneumatics can cover a broad range of technologies from day to day things in a household such as vacuum cleaners (that utilize suction) and certain types of coffee machine to a pneumatic drill (also known as a jackhammer) and jet engine; which is powered forward, but only part, by the rush of gasses that fires out the back through it exhaust. Jet engines on planes utilize combustion as well, yes air is used to be able to combust the fuel and get energy out of it but the way it is utilized does not truly fall under pneumatics. A truly pneumatic place would not use combustion to drive itself forward. (Woodford, 2018)

Types of Pneumatic Devices

Air Compressors

Air compressors can be found in many different places from: petrol stations (used to fill tyres with air), to the manufacturing industry, to car garages and even in home workshops. Air compressors can be found in many different types of models which range in size and are able to handle different jobs, for example compressors built to inflate pool toys and air matrasses as well as being used to power:

- power nail guns

- impact wrenches

- staplers and spray guns

A pro when it come to air compressors is ow lightweight, they can help tools be since each individual tool does no longer need its own individual motor which would add weight and cause the tool to have to be bigger. With air compressors all there is need for is a single motor which has possess the capability to turn electrical energy into kinetic energy. This also means tools can be run quieter, be more easily handled and contain less wearable parts. (Klenck, 2015)

The most common type of air compressor that is encountered by:

- homeowners

- woodworkers

- mechanics

- contractors

are called positive-displacement compressors. With this model of air compressor the air pressure is caused to increase by there being a reduction in the size of space that contains air, most of these kinds of compressors utilize a reciprocation piston like the one found in a combustion engine to achieve this. (Klenck, 2015)

Dynamic compressors are another type of pneumatic device. These devices instead of utilizing the method of physically reducing the size of a pocket of air to cause a raise in temperature instead work by; causing speed up of gasses entering into the impellers (or blades) and then after the gasses exist the blades flows onto a more stationary volume of air which in turn causes the energy caused by velocity to convert into pressure energy (raising pressure). (Bloch, 2017)

Advantages and Disadvantages of Pneumatics

Pneumatics find most of their use in general construction as well as in the mining industry and they are also used a lot in dentistry. Pneumatics technologies counterpart are hydraulics, which instead of using pressurized air use pressurized fluids to be able to carry out mechanical tasks. A common use for hydraulics is:

- hydraulic presses

- hydraulic hoppers

- hydraulic cylinders

- hydraulic rams

whereas some of the most popularly ways in which Pneumatics are used is in:

- Air brakes in buses

- air compressors

- jackhammers

- vacuum pumps

As is known pneumatics compress gas; the science behind it is based on the working principles of fluid dynamics in the concept of pressure. Pneumatic equipment’s utilize a connected series of components in circuit to functions. Circuits tend to be made of working components such as:

- gas compressor

- transition lines

- air tanks,

- hoses

- open atmosphere

- passive components

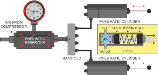

it all functions by having compressed air being supplied by the gas compressor and using several hoses to be able to convey the air through. There are valves whose job is to regulate the air flow and a pneumatic cylinder that converts the pressurised energy delivered by the gas that is compressed into mechanical energy. It is not unusual for inert gases to be also applied, this mainly in the case self-contained systems. Most industries use pneumatics at a gas pressure that range from around 80 to 100psi.

What hydraulic possess over pneumatics is the ability to move heavier loads as well as possessing greater force; on the other hand, pneumatics are also a cleaner system as the system uses no lines of return and its gasses are drained into the atmosphere, this makes leaks less of a concern compared to hydraulic systems which use oil. Pneumatics compressed air is also very accessible and in abundance, this makes it easy to gain a supply and with factories being pre-installed with outlet compressed air able to distribute compressed air it makes setting up equipment and easier job.

References

- Albert Thumann, D. P. (2008). Handbook of Energy Engineering. New York, New York, United States of America: The Fairmont Press, Inc.

- Bloch, H. P. (2017). Petrochemical Machinery Insights. (H. P. Bloch, Ed.) Oxford: Butterworth-Heinemann.

- Brief History of Pneumatics. (2012, February 18). Retrieved from electricstudy.wordpress.com: https://electricstudy.wordpress.com/2012/02/18/brief-history-of-pneumatics/#respond

- ExxonMobil. (2018, July 19). Creating tomorrow’s fuel from unexpected sources. Retrieved December 14, 2018, from energyfactor.exxonmobil.eu: https://energyfactor.exxonmobil.eu/news/algae-timeline/?gclid=EAIaIQobChMIgNLPv5-f3wIVEeJ3Ch3SYAsyEAAYASAAEgLQFvD_BwE

- Klenck, T. (2015, March 18). How It Works: The Air Compressor. Retrieved from www.popularmechanics.com: https://www.popularmechanics.com/home/how-to/a151/how-air-compressors-work/

- Kyle, O. (2014, April 16). Pneumatics through the ages—a timeline of evolution. Retrieved from www.pneumatictips.com: https://www.pneumatictips.com/pneumatics-ages-timeline-evolution-2/

- Woodford, C. (2018, November 27). Pneumatics. Retrieved from www.explainthatstuff.com: https://www.explainthatstuff.com/pneumatics.html

Figure 1Pneumatics system

Figure 2 Pneumatics

Bibliography

- Albert Thumann, D. P. (2008). Handbook of Energy Engineering. New York, New York, United States of America: The Fairmont Press, Inc.

- Bloch, H. P. (2017). Petrochemical Machinery Insights. (H. P. Bloch, Ed.) Oxford: Butterworth-Heinemann.

- Brief History of Pneumatics. (2012, February 18). Retrieved from electricstudy.wordpress.com: https://electricstudy.wordpress.com/2012/02/18/brief-history-of-pneumatics/#respond

- ExxonMobil. (2018, July 19). Creating tomorrow’s fuel from unexpected sources. Retrieved December 14, 2018, from energyfactor.exxonmobil.eu: https://energyfactor.exxonmobil.eu/news/algae-timeline/?gclid=EAIaIQobChMIgNLPv5-f3wIVEeJ3Ch3SYAsyEAAYASAAEgLQFvD_BwE

- Klenck, T. (2015, March 18). How It Works: The Air Compressor. Retrieved from www.popularmechanics.com: https://www.popularmechanics.com/home/how-to/a151/how-air-compressors-work/

- Kyle, O. (2014, April 16). Pneumatics through the ages—a timeline of evolution. Retrieved from www.pneumatictips.com: https://www.pneumatictips.com/pneumatics-ages-timeline-evolution-2/

- Woodford, C. (2018, November 27). Pneumatics. Retrieved from www.explainthatstuff.com: https://www.explainthatstuff.com/pneumatics.html

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal