Development of Vertical Wall Climbing Glass Cleaning Robot

| ✅ Paper Type: Free Essay | ✅ Subject: Engineering |

| ✅ Wordcount: 2597 words | ✅ Published: 18 May 2020 |

Abstract

The development of a robot which can move on the vertical wall that is intended for cleaning the glass wall surface. It is based on passive suction cups mechanism. The robot could then be utilized to carry rescue tools or to do some other work instead of human. Wall climbing robot has the ability to climb on walls, walk ceilings and also can move on the surface of the earth. Centrifugal impeller is employed that generates the low-pressure space for correct adhesion on the vertical wall surfaces. No good protection is needed that is the main advantage of this wall climbing robot. In order to realize this robot, frictional force to the wall, and wheels are crawlers are available as parts of the moving mechanism on flat and wide vertical surfaces. A walking robot with suction cup is more attractive since it can move on a large irregular surface. Many combinations on these ideas can be developed for various applications in the near future. A suction cup with a vacuum pressure is created for climbing and locomotion. A small amount of air is sucked from the peripheral clearance of the cup, when it is moving on the wall, when the brush and/or flexible skirt are employed to prevent air flow at the periphery of the cup. To increase the operation efficiency and to protect human health and safety in hazardous tasks make the wall climbing robot a useful device. The vacuum adhesion module will make the robot to seal the suction in smooth manner.

Overview

Conceptual Working of Glass Cleaning Robot

(Mistry, n.d.)

(Prajapati, n.d.)

(Topiwala, n.d.)

Many researchers have worked on wall climbing robot mechanisms and specialized applications. The summary of major researchers work and their patents are discussed in subsequent paragraphs.

• Tomoaki yano, et al has developed a semi self-contained wall climbing robot with scanning type suction cups which has two vacuum pumps that gave positive results

• James J kerley has conferred in his paper about invention of robotic devices, especially to a mobile robot that is able to move in caterpillar fashion along a variety of different surfaces.

(T.Yano, Self Climbing Robot, n.d.)

“Development of a Wall Climbing Robot II with Scanning Type Suction Cups”, Proceedings of the 2nd ECPD International Conference on Advanced Robotics, Intelligent Automation and Active Systems Changes in social and living environment require supporting works in home and office. Electronics, Mechatronics and Informatics are key technologies to achieve the support system. A robot, which is made by their integration, is expected to be the main equipment. Floor cleaning is usually a tedious, boring and repetitive task and thus a clear candidate for the application of robotics. Researchers in artificial intelligence and robotics have made huge efforts, but it is still an open problem because of unstructured environment of the cleaning operation. Wall climbing mechanisms are helpful systems for the various applications on the vertical surface. Building maintenance is one of the most effective applications of the wall climbing robot. Cleaning of walls is carried out through manual cleaning methods such as use of cables and gondola systems. Recently, we recognize tall buildings covered by glass façades. Wall cleaning at the high places is one of the most laborious and dangerous work, therefore, a lot of research has been conducted for past two decades to liberate human from this laborious and dangerous task.

There are many vertical climbing robots that climb buildings and various other structures through different mechanisms. However each of them has their own limitations. Until now, several types of wall cleaning robots with special locomotion have been proposed. Most of them are using vacuum suction alone as an adhering unit. Some of them have the driving wheels to make continuous movement on the wall. Others use legged motion to make a discreet walking on the wall. But, it is difficult to apply these kinds of vacuum suction based window cleaning robots to the real domestic environments. The robot should be mechanically stable from falling down and must possess an autonomous operating system with no human interference during the entire cleaning stage. Most of vacuum suction based window cleaning robots do not meet such requirements. Some small size window cleaning robots have also been developed during past researches. Also, there are commercially available window cleaning robots such as Windrow, Winbot and robot that clean windows of domestic places. But these are limited to cleaning glass windows indoors. To overcome these above limitations, we have proposed a simple dual purpose cleaning robot in this paper. This robot is capable of cleaning floor and plane glass wall without any obstacles. The robot consists of a base module and cleaning module whose functions will be explained in further sections of this paper. We have used an EDF similar to the one which was used by GECO wall climbing robot for adhering the robot to the wall.

Individual Objectives

• To Fabricate the Low weight plastic chassis.

• Working of Proximity sensor with microcontroller.

• Analysing the behaviour and characteristic of the proximity sensor.

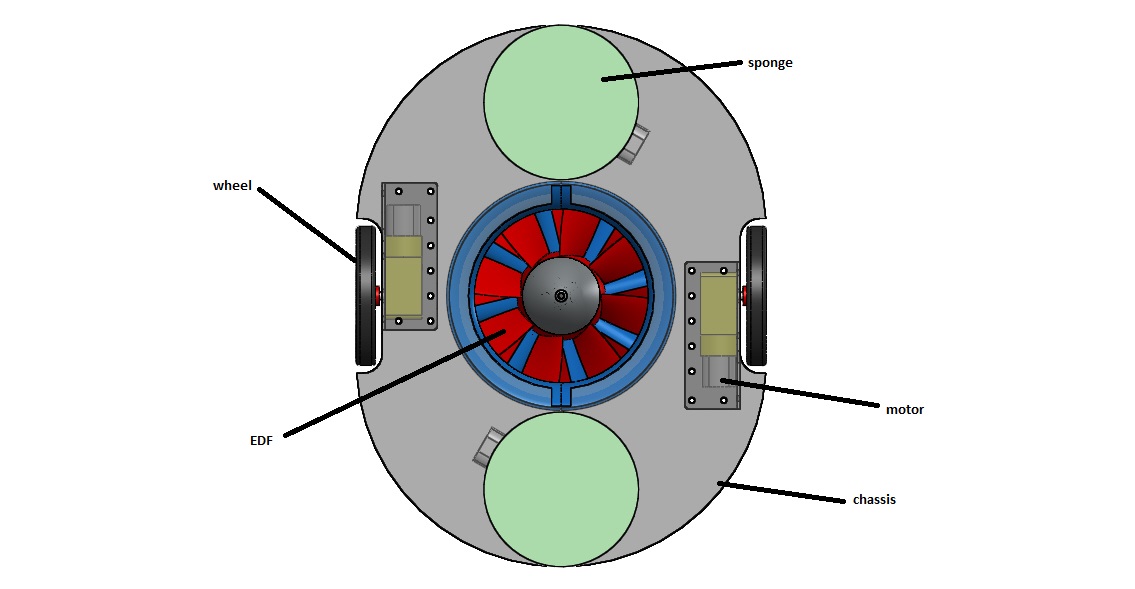

• The prototype of window cleaning robot that we are developing. The dimensions of prototyped robot are approximately 300mm x 300mm x 100mm and its weight is approximately 1-1.5 kg.

• The prototyped robot consists of two independently driven wheels and an active suction cup.

Figure 1 Side View

Figure 2 Isometric View

Project Scope

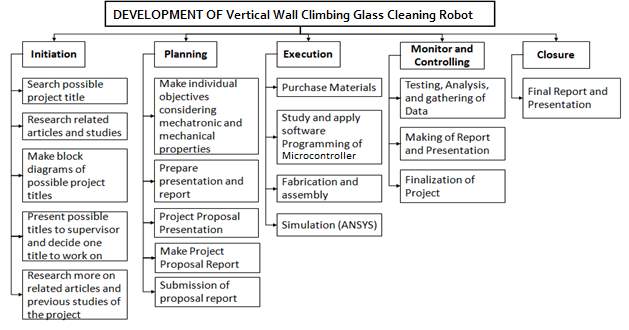

Work Breakdown Structure

Figure 3 WBS CHART

In the above Work Breakdown Structure there are 5 processes Initiation, Planning, Execution, Monitoring and controlling and closure. In initiation process we have researched about various project related to mechatronics engineering and find the suitable title for our project. We have created some block diagram and flow charts for our project. We have also studied the background of the project. In planning we made our individual objectives considering mechatronics and mechanical properties. After that in Execution we have bought materials for the project and starts to fabricate the parts according to planning.

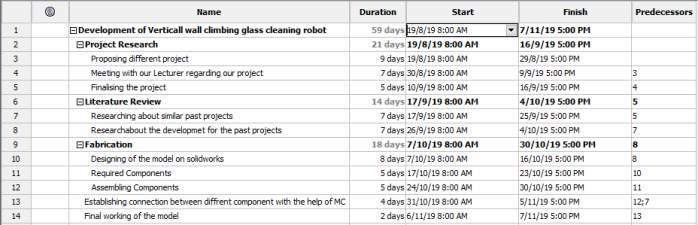

Project Plan and Schedule

Figure 4 Activity Sheet

Figure 5 Gantt chart

Project Methodology and Requirements

The efficient wall climbing robot which can move on the vertical direction as well as ceiling surfaces. Centrifugal impeller is used which generate the low pressure area for proper adhesion on the vertical wall surfaces possible. No perfect sealing is required which is the main advantage of this wall climbing robot.

It requires vacuum impeller to create vacuum and suction motor which rotates the impeller with very high speed and creates vacuum for adhesion system of the wall climbing robot. In centrifugal impeller, air enters from the eye of the impeller and exits radially. The Inlet area where the air enters, creates negative pressure and this is the required adhesion pressure, which is quite helpful for proper adhesion system. An impeller is a rotating component of a centrifugal pump, usually made of iron, steel, bronze, brass, aluminium or plastic. The suction pressure can be easily generated by impeller with backward curved vanes. (Science Direct Assets, 2014)

Figure 6 Flow Chart

Selection of Vacuum Generator

The vacuum generator capacity to empty the suction cup i.e., suction rate VS is governed by the suction cup diameter.

The suction rate V is given by,

V = nV = 16.6 1/min

Where Vs=8.31/min, number of the suction cups n= 2

Hence from, NSCPI 15 Vacuum Generator capable of ejecting 75 l/min is selected. (Wall climbing robot for dust cleaning, n.d.)

Figure 7 Block Diagram

Cleaning Mechanism

A smaller orifice means more suction force because of the increase in pressure that can be attained by the system. Increasing the number of fans improves the cleaning by increasing airflow. The power produced by the suction motor can also dramatically affect performance. To understand the motor and fan design and their role in performance and durability on the system, one must understand two things: impellers and suction motors. The suction motor has to provide a fast enough speed because the impeller is placed directly on its shaft. Suction is derived by centrifugal force. The force acts on the spinning air with the fan because as it rotates, the air moves away from the hub. This creates a slight which causes more airflow into the fan. The more powerful motors contain multiple stage fans pulling in series. Our suction motor will be greater than that used in the current because it will be more powerful and it will be two not one. The cleaning system consists of the brushes in action and the blower power. These components determine how well the dirt is collected. As of now, we feel that by adding brushes and increasing the motor size will do the job. Instead of the one brush underneath robot, we will be using four brushes to maximize cleaning on each side of the robot. The durability of these motors comes into play in the long run, but we have noticed that robot does not offer a market which tends to parts replacement. With that in mind, our robot will give the user the opportunity to change what is broken. (Wall climbing Robot, n.d.)

Components

- Proximity Sensor

We are using Proximity Sensor in our projectbecause of the following reasons:-

-

It can only detects metal object in which the current is flowing.

It can only detects metal object in which the current is flowing.

- Inductive proximity Sensor has highest accuracy among all the other proximity sensors.

- It has non-contact detection of the object.

- It has Short response type.

- It has a long life due to non-contact output.

- It can’t detects non-metal objects in which current is not flowing.

- Micro Controller 89V51

-

Compatible with MCS-51™ Products

Compatible with MCS-51™ Products

- 4K Bytes of In-System Reprogrammable Flash Memory –

- Endurance: 1,000 Write/Erase Cycles

- Fully Static Operation: 0 Hz to 24 MHz

- Three-level Program Memory Lock

- 128 x 8-bit Internal RAM

- Suction Cups

- DC geared motors

- Wheels

- Low weight plastic chassis

- LIPO battery

- Centrifugal Impellor

Figure 8 Components

Figure 9 Flowchart for cleaning mechanism

Brush Optimization

The brushes that will be used will be expected to rotate at 4500 RPM. This transmitted centrifugal force will translate to a lot of stress on the rod. A finite element analysis was performed to measure its Von Mises stress and its max displacement. The max Von Mises stress on the assembly is which is reasonable because we are using 765psi ABS. It has a very high plastic deformation threshold. You will find the Von Mises stress and deformation. The components consist of the proximity sensors the bumper, motor, mount the microcontroller the battery the blower the display screen and the wireless transmitter. (web.stevens.edu, 2017)

Conclusion

• The application of small-size and light weight wall climbing robots for window cleaning. The window cleaning robot consists of two-wheel locomotion mechanism and a suction cup.

• This robot has a function to change a traveling direction at right angle at the corner of the window.

• This robot moved on the window smoothly with adhering by a suction cup.

• It is used to climb the wall safely and overcome its gravity, should avoid the human injuries.

• To reduce the human effort.

• Time consumption for dust cleaning purpose in a household buildings.

Future Applications

With little or no modification, the climbing robot can be used for the following applications and also its advantages are mentioned.

• It can be a replacement for GONDOLA system for high rise building cleaning

• It has the potential to serve as a base on which to mount data acquisition devices, surveillance equipment, or object-manipulation tools

• Wireless/wired video surveillance can be possible.

• Public safety & military applications (surveillance, search & rescue)

• Consumer applications (window cleaning and painting)

• Inspections (building, aircraft & bridges, Pipes) etc.

• Wall/glass cleaning and water sprinklers can be mounted.

• On board vacuum cylinders are not used, which increases payload capacity.

Work Cited

Bibliography

- Mistry, J. A. (n.d.).

- Prajapati, H. N. (n.d.).

- Science Direct Assets. (2014, March). Retrieved from pdf.sciencedirectassets.com: https://pdf.sciencedirectassets.com/280203/1-s2.0-S1877050918X0009X/1-s2.0-S187705091831010X/main.pdf?X-Amz-Security-Token=AgoJb3JpZ2luX2VjEPT%2F%2F%2F%2F%2F%2F%2F%2F%2F%2FwEaCXVzLWVhc3QtMSJHMEUCIGbK5hUkFy0lFUIr7zrHAnYKt%2FARXRHx4FZv8RTNze%2FtAiEAx973U05R

- T.Yano, T. K. (n.d.).

- T.Yano, T. K. (n.d.). Self Climbing Robot. Retrieved from https://www.researchgate.ne: https://www.researchgate.net/publication/326538175_Portable_Autonomous_Window_Cleaning_Robot/link/5bbdcc31a6fdccf2978f08f3/download

- Topiwala, U. V. (n.d.).

- Wall climbing Robot. (n.d.). Retrieved from Researchgate: https://www.researchgate.net/publication/255584440_Gecko_a_climbing_robot_for_walls_cleaning/link/53f4cd950cf22be01c3ee564/download

- Wall climbing robot for dust cleaning. (n.d.). Retrieved from http://ijariie.com: http://ijariie.com/AdminUploadPdf/Pneumatic_powered_wall_climbing_robot_for_dust_cleaning_purpose_in_a_high_risk_building_s_IJARIIE7466.pdf

- web.stevens.edu. (2017, Feb). Retrieved from https://web.stevens.edu/ses/me/fileadmin/me/senior_design/2007/group01/DesignFinal.pdf

Evaluation report

Self-evaluation

In this project I have seen some desirable and undesirable outcomes during the planning phase. First of all I want to tell that selection of our project takes more than 4 weeks as your two project title got declined by our professor. After finalising the project title we started working on the project that what modifications we can do to make it even better. I did research on the chassis of the project to make it light weight to stick on the wall and to prevent from falling. I went to the Jaycar in New Zealand to find the suitable plastic for my chassis. I also researched about the different kind of sensor which I can use in my project. I found that proximity sensor will work perfect respectively to the microcontroller for my project.

Peer evaluation

Besides me there are two more people in my group Manpreet Singh and Harish Sharma. Manpreet is working on two stepper motor that has been installed under the chassis and to control the movement and speed of the prototype respectively to suction cups that has been installed to stick it on the walls. He is also working on the LIPO Battery to give the suitable Voltage to the machine to work smoothly on the glass.

On the other hand Harish Sharma is working on the Adhesion System and suction cups to prevent it from falling while running with respect to Stepper motor torque and voltage requirement for it to run smoothly on the surface.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal