Human Error Theories and Workplace Incidents Caused by Human Failure

| ✓ Paper Type: Free Assignment | ✓ Study Level: University / Undergraduate |

| ✓ Wordcount: 5964 words | ✓ Published: 02 Sep 2021 |

There have been an increasing number of incidents at your workplace and the investigations carried out have shown that human failure has contributed to these incidents. The Directors of the organisation have asked you to write a report to assist them in managing human failure, with the aim of reducing the number of incidents that are occurring. Your report should include the following Assignment Brief:

- An outline of the variations of human failure

- The approaches that could be taken by the organisation to control each type of failure

- The impact stress can have on human failure

- The steps the company should take to assess the risk from work related stress

Contents

1.2 Key Areas – Policy/Procedure Implementation

5 Categorisation of Human Error

5.3 Slips and Lapses (Skill based)

5.5 Mistakes (Knowledge Based)

6 Factors that Influence Human Error

7.2 Identify Critical Human Tasks

7.3 Understand the Task Process and Performance Shaping Factors

7.5 Devise Safety Measures to Control Human

7.6 Review the Effectiveness of the Process

8 How Can We Shape Human Behaviour to Prevent Accidents

9 Stress, Human Error and Accident Causation

10 Occupational Stressors within the Construction Industry

11 Overview of Occupational Stressors Related to Human Error

12 A Risk Management Approach to Organisational Stress

1 Executive Summary

Human error has been consistently cited as contributing factor in many major incidents particularly in Industries with a high operational risk such as construction. Workers are faced with numerous hazards and these combined with the addition of human error and negligent oversite can often result in catastrophic events.

The overall safety performance of the organisation is dependent on the safety measures it adopts in controlling such risks. The integration of human factors and the effects that stress can pose on an individual will need to be integrated into the current safety management matrix to ensure risk areas are identified and effective solutions put in place to mitigate against any potential loss.

This report is intended to provide guidance to senior executives by producing an over view of human error theories and the impact stress can have on an individual’s performance. It is designed to equip them with an understanding of the factors that influence human errors and facilitate a strategic approach in managing and controlling the risk successfully. The report will review background literature and prior research to provide key recommendations for policy implementation.

1.1 Key Observations

- Human error is a significant source of risk in any organisation and has consistently been cited as a major causal factor in a high proportion of accidents and incidents.

- Human errors start at the design stage. From processes, procedures to training and the workplace environment many factors that influence human behaviour can be engineered reducing the likelihood of these occurrences.

- The construction industry has always been considered as one of the most dangerous industrial sectors and any successful attempt to improve process safety must address human error and the impact of psychological injury on human behaviour.

- The way to reduce human error and prevent accidents is through effective management such that safety is considered important by everyone involved

1.2 Key Areas – Policy Implementation

- A six-step process will be adopted which will focus on the implementation of control measures to prevent and mitigate against the possibility of error occurrence. The risk management strategy will combine individual and organisational interventions.

- The HSE Management Standards on Stress approach will be used to determine the causes of stress and identify suitable control measures. Six key areas of work that can have a negative impact on health will be focused on. These are: demands, control, support, role, change and relationships.

- Use internal specialists and experts in root-cause analysis. These experts need to be viewed as independent and should be trusted so there is no fear of a comeback. The approach needs to have a light touch, recognising that middle managers may be defensive about discussing mistakes made in their plants.

1.3 Key Areas – Pre Requistes for success

- Sustained top management support is a pre-requisite to success.

- Success requires a participative and cooperative approach with employees.

- Action planning is vital with clear tasks and responsibilities laid out. A steering committee and working group will be established to oversee the project

2 Introduction

2.1 Background

Human error is apparent in everyday life and it is inevitable that human beings will make mistakes. Research shows that factors such as lack of skills, experience, environment and organisational circumstances can significantly increase the prevalence of human errors. No matter how well trained and motivated an individual is, the consequences of human failure can be severe and can often result in catastrophic events.

The construction sector has long been identified as one of the UK’s highest risk industries. Although it accounts for only about 7% of the UK workforce, the sector still accounts for 22% of fatal injuries (HSE, 2017) to employees making it responsible for 1 in 5 deaths. The industry involves physically demanding work by its very nature and workers constantly have to adapt to deal with changes in the nature of the work, the hazardous environment and working to tight deadlines.

Managing the impact of human error within the construction industry is a challenge given the variability in the work, and the transient nature of the workforce. Whilst in recent years we have seen an increase in the management of safety risk, “human error remains an increasingly frequent factor in many accidents” (Rasmussen; Smith 2000). It has been estimated that 90% of accidents have resulted due to an element of human failure in part (Shotwell, 2018). Over the last 20 years in the UK, 27% of fatal and 10% of major injuries were construction related (Asanka and Ranasinghe, 2015).

The relationship between human error and stress has also been the subject of much academic research. Adams (1980) suggests that there is a plausible relationship between human error and worker stress in the workplace. According to DuBois and Hurrell (1986) stress related factors such as anxiety, fatigue and reduced motivation might compromise employee performance increasing the risk of human error and accidents. In a safety critical industry such as construction the effects can significantly increase the probability of accidents occurring and require close management to minimise the potential of harm. Whilst the human risks cannot be eliminated completely, human error can be moderated by effective management.

2.2 Purpose of the Report

A recent analysis of company accident data has identified that human failure has been a significant contributing factor in the increase of workplace accidents. This report is aimed at the board of directors of ABC Construction and seeks to review human failure theories and the relationship between stress and the impact on human error. Furthermore, the identification and management of human factors will be explored to enable the implementation of targeted solutions to improve human reliability and mitigate its consequences.

In order to reduce the accident rate within the organisation we need a thorough understanding of:

- The different types of human error to determine how they contribute to the causes of accidents on construction sites.

- How Human factors can be integrated into the safety management systems to help reduce accident occurrence.

- The relationship between the effects of stress and Human error.

- A strategic approach to enable the implementation of a robust risk management approach to stress.

This report will provide an understanding of Human Factors and Human Behaviour to help identify risk and prevent accidents and incidents before they occur.

3 The Construction Sector

The Construction industry is one of the largest in Great Britain and is also one of the most hazardous due to the high-risk nature of the activities and tasks that are undertaken. Tackling health and safety management within the sector is a considerable challenge given the transitory nature of projects. Processes are often complex and vary in scale and the workforce can almost change on a daily basis. Intense deadlines and economic pressures can lead to tendencies of complacency when it comes to safety with the aim of simply getting the job done to avoid any penalties.

The seriousness of hazards associated with construction activity is evident from a number of highly publicised accidents. The collapse of the Westgate Bridge in Melbourne Australia resulted in the death of 30 workers. The collapse of scaffolding at Willow Island, West Virginia led to the death of 51 workers and was established to be as a result of a series of errors and shortcuts in haste to complete the project on time.

4 What is Human Error

Human error has been identified as the root cause in several major disasters such as the Bangladesh Building Collapse, Deepwater Horizon oil spill and the Bhopal Disaster.

The subject has been studied by several theorists who have proposed various typologies for human error. Reason defined human error as “Planned actions that fail to achieve their desired consequences without the intervention of some chance or unforeseeable agency” (Reason, 2009). Human error was categorised further by Reason in terms of slips, lapses, mistakes and violations which are discussed further below. The definition has been further expanded to account for the effects of individual, group and organisational factors on safety.

5 Categorisation of Human Error

5.1 Active errors

Active failures are the result of unsafe acts committed by those at the front end of the system i.e. the actions carried out by the individual involved in the performance of the task. These actions can have immediate adverse consequences such as ignoring a warning light on a machine.

5.2 Latent errors

Latent errors refer to less apparent failures of organisation or design that contributed to the occurrence of errors or allowed them to cause harm to workers. They are generally created as a result of decisions taken by management and may lie hidden for long periods, only surfacing when they combine with other factors. Latent failures are much easier to rectify to prevent the occurrence of an accident when active monitoring is in place.

5.3 Slips and Lapses (Skill based)

These can be caused by lack of concentration or attention and result in the failure to carry out the correct actions of a task such as using an incorrect switch. Lapses can be defined as failures to carry out particular actions which form part of a working procedure such as stepping into a hole in a walkway. Skill-based errors generally occur when highly routine activities are being carried out when attention is diverted from the task. The task has most likely been performed in correct manner several times before and therefore becomes routine in a familiar situation requiring less conscious attention. This type of error is more prevalent in experienced individuals who have the required skills to carry out the task.

5.4 Mistakes (Rule Based)

Mistakes are incorrect judgments. At the rule based level the incorrect application of a rule or procedure is applied which in turn may be caused by a misinterpretation of the problem situation.

5.5 Mistakes (Knowledge Based)

Knowledge-based mistakes: At the knowledge based level, error occurs when there is a failed effort to correct the situation without tools, training or any prior warning. These errors are the most difficult to prevent given that it is hard to predict and foresee.

5.6 Routine Violations

Typically involves cutting corners and usually occurs when violations of procedures become normal practice such as taking shortcuts to save time such as using an unsecured ladder.

5.7 Situational Violations

A situational violation occurs in response to situational factors, such as excessive time pressure to finish a task, design of equipment, or inadequate equipment which make it easier to take a shortcut rather than follow the safe working method such as using a ladder instead of scaffolding when working at height.

5.8 Exceptional Violations

Exceptional violations happen when something has gone wrong. To solve a new problem, an individual feels they need to break a rule, even though they are aware that they will be “taking a risk”.

6 Factors that Influence Human Error

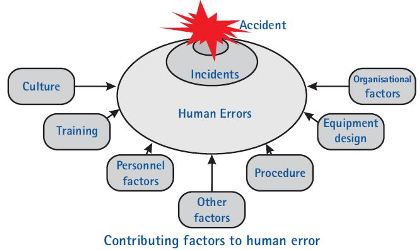

The HSE define human factors as “environmental, Organisational, job factors, and human and individual characteristics which influence behaviours at work in a way which can affect health and safety” (HSE, 1999)

Figure 1: Contributing Factors to Human Error

7 Reducing Human Error

Human factors can be difficult to quantify and effective risk management requires a disciplined and structured approach. To focus on Human Performance Factors a competent Human Factors engineer will be recruited within Occupational Health and Safety. A six-step process will be adopted which will focus on the implementation of control measures to prevent and mitigate against the possibility of error occurrence.

7.1 Identify Site Hazards

In order to identify safety critical tasks it is important to collate data on the primary hazards that a site is faced with. This will be conducted through consultation with site personal, the examination of current risk assessments and accident records/investigations to ensure that a comprehensive hazard register is collated.

7.2 Identify Critical Human Tasks

“Critical human tasks are defined as those activities people are expected to perform as barriers against the occurrence of an incident, or to prevent escalation in the event that an incident does occur”. This stage involves analysing the site hazards identified and looking at which procedures involve human tasks. A risk assessment approach to calculate the severity of error and the consequences of these can be applied to evaluate the overall risk.

| Consequences of Human error | Severity of occurrence |

| High | Human error could result directly in a major accident hazard |

| Medium | Human error could escalate to a major accident hazard if other prevention barriers fail |

| Low | Human error should not directly lead to a major accident hazard. |

|

Consequences |

M | H | H |

| L | M | H | |

| L | L | M | |

| Degree of Human Involvement | |||

Figure 2: Risk Assessment Matrix Example

7.3 Understand the Task Process and Performance Shaping Factors

This stage involves gaining an understanding of the critical human tasks by establishing what is done by who, the equipment/machinery required, the amount of people required to carry out the task and the working conditions which may affect human performance. (Figure 3) PSFs identified that most likely influence errors can be targeted to develop more robust control measures.

| Individual | Job | Organisation |

| Fatigue | Working environment (noise, ventilation, light) | Inadequate staffing |

| Substance Abuse | Work load / Task complexity | Safety culture |

| Level of competence | Relationships with Co Workers and Management | Communications |

| Attitude towards Safety | Protocols/Procedures | Leadership commitment |

| Motivation | Time constraints | Project planning |

Figure 3: Performance Shaping Factors

7.4 Identify Error Potential

A granular description of the task processes should then be outlined to identify potential errors. This will also identify tasks that are not covered by documented procedures. To aid in identifying appropriate controls it is important to classify the type of error. For example, knowledge and rule-based mistakes can be mitigated and to an extent, prevented through appropriate training and competency within the area. However, these controls tend to be less effective when it comes to skill-based errors such as memory lapses which can occur during task execution.

7.5 Devise Safety Measures to Control Human

The implementation of risk controls is fundamental to reducing the likelihood of human error. The actions of individuals need to be considered in close conjunction with performance shaping factors. Where an identified human error hazard cannot be eliminated in its entirety, concentration needs to focus on whether the consequences of human error can be mitigated by additional safety barriers and the improvement of identified performance shaping factors.

When devising safety measures hazards will also need to be categorised into the types of potential errors that may occur as discussed above i.e. slips/lapses, mistakes and violations to determine the most effective control measures. For example, introducing check lists on site to confirm that actions have been completed will reduce slips and lapses and taking steps to minimise distractions and interruptions. Simplifying complex procedures with visual aids and improved training could impact mistakes and violations.

| Task Description | Potential Human Error | Performance shaping factors | Consequences | Measures to prevent or reduce |

| Isolate machinery prior to maintenance | Failure to complete or reverse isolations fully before starting work or restarting plant | Competence Procedures, Communication, safety signage | Potential for severe Injury | Task risk assessment for isolation. Review communications for shift change over Clear visible safety signage

Adequate training |

Figure 4: Example Human Error Risk Assessment

7.6 Review the Effectiveness of the Process

Regular reviews of the process should be carried out to review the success of the measures that have been implemented. Key performance indicators such as accident rate will establish a framework with which to identify areas where human error can have adverse consequences and identify any gaps in the defence barriers.

8 How Can We Shape Human Behaviour to Prevent Accidents

- Better Safety Culture: Encourage personnel to follow safety rules within a just and fair culture where all feel able to raise concerns about equipment design, operating procedures, training etc.

- Better Supervision: Focus on getting the job done safely and not just on getting the job done. Supervisors should ensure that all are aware, not only of the accidents that might happen, but also, the likely consequences of those accidents.

- Better perception of risk: Consider how human fallibility can interact with poor working conditions to cause accidents. Learn how to recognise these factors and take action before an accident or incident occurs.

- Better leadership: Consider how leadership can be used to encourage safety awareness, behaviour and culture.

- Better communication and feedback: Focus on communicating risks and accident feedback to inform behaviour if a similar situation arises. An accident may be prevented by early identification of hazards. Report all accidents, incidents and near misses.

9 Stress, Human Error and Accident Causation

Work related stress is recognised as a major challenge for organisations globally and can have serious consequences on an individual. The HSE define stress as “The adverse reaction a person has to excessive pressure or other types of demand place upon them” (HSE, 2005). Occupational stress can also be described as “a process, involving a transaction between an individual and his/her work environment” (Michailidis, 2009).

“Stress is not limited to any particular profession“ (Ng, Skitmore and Leung, 2005). However, Statt (1994) noted that construction work is the third most stressful profession after mining and police work. Stress plays an important role in the reliability of a person performing a certain task and the physically demanding nature of the job along with the pressure to complete projects within deadlines, can all induce the possibility of stress. Furthermore, the macho perception of the industry can result in a reluctance to seek help to address the factors that have led to stress.

It is foreseeable that stress can play a contributing factor to accident causation. Dr David Spielberg notes that “It’s very clear that a big proportion of safety problems are due to human error, and some of that is related to stress” (Stress and worker safety, 2018). Stress results in distraction which effects concentration and the ability to follow instructions which in turn increases the chances of accidents occurring. A review by Murphy Dubois and Hurrell (1986) also concluded that there is some evidence which indicates the existence of an association between stress and workplace accidents.

10 Occupational Stressors within the Construction Industry

Construction organisations operate in a highly competitive market. When project deadlines are not met, companies are then exposed to considerable penalties so work hours are frequently long and at times irregular. Many construction roles require employees to work regular weekends which previous research shows to be linked to job stress, burnout and health problems (Jamal 2004).

An investigation carried out by Goldenhar, Williams and Swanson (2003) of 408 construction workers concluded that 10 out of 12 job stressors directly related to either injury or near misses including “job demands, low job control, job uncertainty, low training, unsafe climate, skill under- utilization, irresponsibility for the safety of others, safety compliance, exposure hours and job tenure” (M. Goldenhar*, Williams and G. Swanson, 2003).

A research report carried out by the Chartered institute of Builders in 2006 whose sample consisted of 847 construction professionals found that the majority of respondents (68.2%) had suffered from stress, anxiety or depression as a direct result of working in the construction industry. The most common causes in the study were found to be: lack of feedback (56.8%), poor communication (55.7%), inadequate staffing (55%), too much work (64.1%), ambitious deadlines (59.7%), pressure (59.9%) and conflicting demands (52.2%). (Campbell, 2006)

From existing literature, a number of themes emerge, namely that those working in the construction sector experience a number of stressors including long working hours, work overload, role conflict and insecurity, relationships with other construction employees, job insecurity, time pressures and cost pressures.

11 Overview of Occupational Stressors Related to Human Error

- Task demands inherently found within the sector include excessive workloads, concerns over time pressure and cost pressures and conflicting roles which impact both managerial and blue collar workers.

- Physical demands. Common stressors associated with the physical working environment include inadequate lighting, noise, vibration, restricted working space, temperatures, working with hazardous substances and strenuous activities.

- Role demands are stressors associated with a particular position in a group or organisation. Examples of which include inadequately defined roles which result in role ambiguity and interpersonal conflicts that often occur when working in group situations.

- Interpersonal demands are stressors associated with the characteristics of the relationships and include conflict, poor communication, sour relationships and lack of support from colleagues.

12 A Risk Management Approach to Organisational Stress

A robust risk management strategy requires careful planning and oversite. A senior steering committee will be established to include various members of the management team from Health and Safety, Human resources, and operational management who are responsible for policy, procedures and related matters affecting the organisation as a whole. The committee will provide guidance and direction and to act as an interface within the organisation.

A working group will also be established to ensure that the recommendations are implemented correctly and will include members who are actively involved in the day to day processes of the operation, i.e. site foreman, supervisors and team leaders. The working group will encourage employee participation, analyse and prioritise key areas where intervention is needed.

A number of factors are required for the successful implementation success:

- Commitment from senior management is a critical part to the success of this kind of intervention.

- Employee consultation and participation is essential at every level throughout the process stages. Employees are the most knowledgeable on the working environment and in constant close contact with the daily processes. Their experience will provide first-hand knowledge of the elements that can increase the risk of work-related stress. Consultation will also inspire the workforce to accept and conform to the resolutions that will be implemented.

- Gaining employee commitment through regular and transparent communication will assist in successfully changing attitudes and behaviour towards safety

- Providing feedback on the risk assessment is fundamental. This ensures that the information gathered about risk factors is used in designing, implementing and evaluating appropriate interventions.

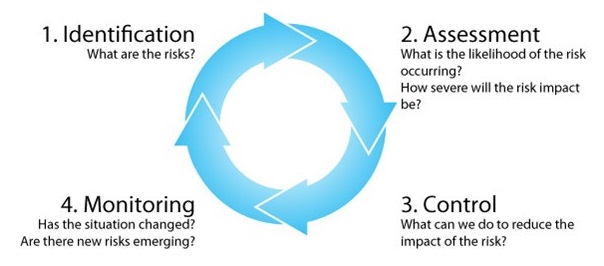

12.1 Risk Management Process

PLAN

Figure 5: Risk Management Process

12.2 Identify the Hazards

The first step in the process is to identify the hazards. During this phase, it is essential that staff are consulted. They should be encouraged to communicate their views, particularly identifying stressors within their role so an accurate reflection of the risks can be identified. This will be achieved by:

- Setting up small focus groups to provide a forum for discussing and assessing the risk of exposures to work related stressors.

- Anonymous Staff satisfaction surveys will be conducted to assist further in identifying stressors and pinpoint areas to which they are originating.

- Reviewing sickness and absence data and referrals to occupational health

- Accident report forms will be evaluated to identify any stress related contributing factors.

- Feedback obtained during exit and return to work interviews.

- Observing workers during their daily activities to watch for factors that could lead to stress, e.g. low morale, poor relationships with colleagues and lack of motivation.

12.3 Assess the Risk

Once the hazards have been identified the risk factors associated with these will need to be addressed. The HSE have developed a set of management standards that cover six key areas of work design. This approach will be adopted and the following areas will be considered during this phase:

| Factor | Example Considerations |

| Demands |

|

| Control |

|

| Support |

|

| Relationships |

|

| Change |

|

| Role |

|

12.4 Controlling the Risk

During this phase the risk control measures should address risks associated with the causes, and should consider the hazards identified above. Once the risks have been assessed reasonable control levels need to be selected and implemented. For the risks that have been identified a solution will need to be identified which either eliminates or controls that risk. Examples of control measures to manage the risk of work-related stress may include:

| Factor | Example Control Measures |

| Demands |

|

| Control |

|

| Support |

|

| Relationships |

|

| Change |

|

| Role |

|

12.5 Review control measures

The final step in the process involves reviewing the effectiveness of the control measures by regular audit and feedback to ensure the implemented control measures are operating as intended. This phase will identify whether the control measures are adequate or if they require modification.

It is imperative that Risk management for work-related stress is not treated as a one-off exercise, but something that must continue to grow and adapt with the organisation. As processes advance and the workforce changes these can bring along new effects on the stress levels encountered by the workforce and only by constantly reviewing these will they be identified.

The frequency of how often the measures should be reviewed is not an exact science however the following trigger points will provide some guidance:

- Where the implemented control measure fails or produces negative outcomes

- Where a change within the workplace which gives rise to a new stress related risk

- Where a new hazard or risk is identified

- Where concerns have been raised by employees through surveys and consultation forums.

13 Conclusion

The construction sector has witnessed profound institutional and organisational transformation over the last decade in response to technological advancement and increased regulation. Consequently, workers are faced with the pressures of operating in an ever increasingly competitive environment to ensure projects are delivered within time frames and tight budgets. All of these factors combined result in a very mentally, physically and emotionally demanding work environment which in turn increases the inevitably of accidents occurring.

Human error is a significant source of risk within any organisation. The costs of these errors can not only result in serious injury but also financial consequences and subsequent damage to the organisations reputation. The benefits of human error analysis can identify remedial actions to reduce the likelihood of errors occurring and increase the reliability of the overall plant process

This report has examined the factors which influence human error and established that errors are more likely to occur when stressors impact human reliability, consequently reducing the individual’s capability to perform effectively. It is important that employers recognise stress as a significant health and safety issue and adopt a robust risk management approach to identify and control stressors within the workplace.

Whilst Human error is impossible to eradicate completely control factors that focus on human error aspects such as equipment design and usability, task and job design, workplace design, procedures, training, communication, team work, supervision, and monitoring can be adapted to control the chances of errors occurring.

Accident reduction can be achieved successfully by learning from errors, rather than seeking to attribute blame. The analysis of information from accidents and near misses can be utilised to implement effective design and management solutions to reduce future accidents occurring. By identifying the involvement of human factors new and better measures can be implemented to reduce the frequency and minimize the consequences. Furthermore, the effective management of stress related illnesses will further guard against the chances of accident occurrence.

14 Recommendations

- Human Factor analysis will be integrated into Risk assessments where processes and procedures have identified opportunities for human error.

- An inventory of operations and maintenance tasks considered to be essential in ensuring process safety will be collated.

- Once the key errors have been identified and classified, relevant PSFs will be explored to determine their likely contributions to each error.

- Controls will be implemented to ensure that the risk posed by error is as low as reasonably practicable.

- Management and employees involved in Health and Safety will be sufficiently trained to understand the impact of psychological injury and how this can impact on safety.

- Psychological ill health will form part of the accident investigation process where necessary.

- Accident investigation/analysis frameworks will be developed to ensure a more detailed inquiry is included in cases that could involve psychological ill health.

- Identifying their risk or potential exposure to occupational stress in the workplace and outlining key issues in developing local prevention and management strategies.

15 References

Figure 1 – Factors Influencing Human Behaviour – Management Platform for Human Resource Development in the Field of Industrial Disaster Risk Management (2018). Available at: http://www.hrdp-idrm.in/e5783/e17327/e28013/e28938/ (Accessed: 2 March 2018).

Figure 5 – procurementjourney.scot (2016) Risk Management Process | Procurement Journey, Procurementjourney.scot. Available at: https://www.procurementjourney.scot/risk-management-process (Accessed: 12 February 2018).

Stress and worker safety (2018) Safetyandhealthmagazine.com Available at: http://www.safetyandhealthmagazine.com/articles/14300-stress-and-worker-safety (Accessed: 10 February 2018).

Adams, J. (1980) Understanding and managing stress. San Diego, CA: University Associates.

Asanka, W. and Ranasinghe, M. (2015) Study on the impact of accidents on Construction projects, Civil.mrt.ac.lk. Available at: http://www.civil.mrt.ac.lk/conference/ICSECM_2015/volume_4/Extract/SECM-15-088.pdf (Accessed: 9 February 2018).

Campbell, F. (2006) Occupational Stress in the Construction Industry, Ciob.org. Available at: http://www.ciob.org/sites/default/files/Occuptaional Stress in Construction.pdf (Accessed: 9 February 2018).

Davies, W. (2016) Can Human Error be avoided in the construction sector? – iHasco, Ihasco.co.uk. Available at: https://www.ihasco.co.uk/blog/entry/1445/can-human-error-be-avoided-in-the-construction-sector (Accessed: 9 February 2018).

Heinrich, H., Petersen, D. and Roos, N. (1980) Industrial accident prevention. New York: McGraw-Hill.

Hollnagel, E. (1993) Human reliability analysis. London: Academic Press.

HSE (2017) Health and safety statistics for the construction sector in Great Britain, 2017, Hse.gov.uk. Available at: http://www.hse.gov.uk/statistics/industry/construction/construction.pdf (Accessed: 9 February 2018).

HSE (1999) Reducing error and influencing behaviour, Hse.gov.uk. Available at: http://www.hse.gov.uk/pubns/priced/hsg48.pdf (Accessed: 9 February 2018).

HSE (2005) Working together to reduce stress at work, Hse.gov.uk. Available at: http://www.hse.gov.uk/pubns/indg424.pdf Accessed: 9 February 2018).

Karwowski, W. (2006) International Encyclopedia of Ergonomics and Human Factors, Second Edition – 3 Volume Set. Hoboken: CRC Press, p. 2652.

Kontogiannis, T. and Embrey, D. (1992) Human reliability assessment. Practical Techniques for Assessing and Reducing human error in industry.

legislation.gov.uk (1999) The Management of Health and Safety at Work Regulations 1999, Legislation.gov.uk. Available at: http://www.legislation.gov.uk/uksi/1999/3242/contents/made (Accessed: 2 March 2018).

M. Goldenhar*, L., Williams, L. and G. Swanson, N. (2003) “Modelling relationships between job stressors and injury and near-miss outcomes for construction labourers”, Work & Stress, 17(3), pp. 218-240. doi: 10.1080/02678370310001616144.

Michailidis, M. (2009) Faculty Stress, p. 193.

Murphy, L., DuBois, D. and Hurrell, J. (1986) “Accident reduction through stress management”, Journal of Business and Psychology, 1(1), pp. 5-18. doi: 10.1007/bf01014163.

Ng, S., Skitmore, R. and Leung, T. (2005) “Manageability of stress among construction project participants”, Engineering, Construction and Architectural Management, 12(3), pp. 264-282. doi: 10.1108/09699980510600125.

Reason, J. (2009) Human error. New York, N.Y: Cambridge University Press.

Shotwell, H. (2018) Human Error Is Not the Real Cause of Accidents – Atlantic Environmental | Atlantic Environmental, Atlenv.com. Available at: https://www.atlenv.com/human-error-accidents/ (Accessed: 9 February 2018).

Stratt, D. (1994) Psychology and the World of work, p. 93.

16. Bibliography

Addressing the Root of the Stress Problem in Construction – LHSFNA (2018) Lhsfna.org. Available at: https://www.lhsfna.org/index.cfm/lifelines/september-2015/addressing-the-root-of-the-stress-problem-in-construction/ (Accessed: 9 February 2018).

Berry, M. (2018) Stress increases in construction industry – Personnel Today, Personnel Today. Available at: https://www.personneltoday.com/hr/stress-increases-in-construction-industry/ (Accessed: 9 February 2018).

HSE (2007) An analysis of the prevalence and distribution of stress in the construction industry, Hse.gov.uk. Available at: http://www.hse.gov.uk/research/rrpdf/rr518.pdf (Accessed: 9 February 2018).

Human Error in Construction Project Delivery | IRMI.com (2018) Irmi.com. Available at: https://www.irmi.com/articles/expert-commentary/human-error-in-construction-project-delivery (Accessed: 9 February 2018).

Human Resource Management in Construction Projects (2003) Google Books. Available at: https://books.google.co.uk/books?id=UqoBhfFDQsoC&dq=construction+industry+and+stress&source=gbs_navlinks_s (Accessed: 9 February 2018).

Implementation of Safety and Health on Construction Sites (1999) Google Books. Available at: https://books.google.co.uk/books?id=PsyqmXJmczMC&dq=HUMAN+ERROR+CONSTRUCTION+INDUSTRY&source=gbs_navlinks_s (Accessed: 9 February 2018).

NOPSEMA (2015) Human error risk reduction to ALARP, Nopsema.gov.au. Available at: https://www.nopsema.gov.au/assets/Information-papers/A424182.pdf (Accessed: 16 February 2018).

Occupational Stress – an overview | ScienceDirect Topics (2018) Sciencedirect.com. Available at: https://www.sciencedirect.com/topics/biochemistry-genetics-and-molecular-biology/occupational-stress (Accessed: 9 February 2018).

Stress at work – Work-related stress and how to tackle it – HSE (2018) Hse.gov.uk. Available at: http://www.hse.gov.uk/stress/what-to-do.htm (Accessed: 9 February 2018).

Stress Management in the Construction Industry (2014) Google Books. Available at: https://books.google.co.uk/books?id=oBQHBgAAQBAJ&printsec=frontcover&dq=construction+industry+and+stress&hl=en&sa=X&ved=0ahUKEwjT5aDV2pnZAhWNW8AKHWatD30Q6AEIKTAA#v=onepage&q=construction industry and stress&f=false (Accessed: 9 February 2018).

Understanding Human Failure (2018) Hse.gov.uk. Available at: http://www.hse.gov.uk/construction/lwit/assets/downloads/human-failure.pdf (Accessed: 9 February 2018).

Work-related stress and mental illness is worse in construction (2018) BSG’s secure membership area. Available at: https://www.bsgltd.co.uk/work-related-stress-mental-illness-worse-construction/ (Accessed: 9 February 2018).

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this assignment and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal